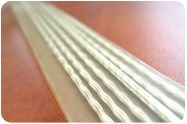

Ribbon Cable Design Features

Send Us Your Questions

Send Us Your Questions

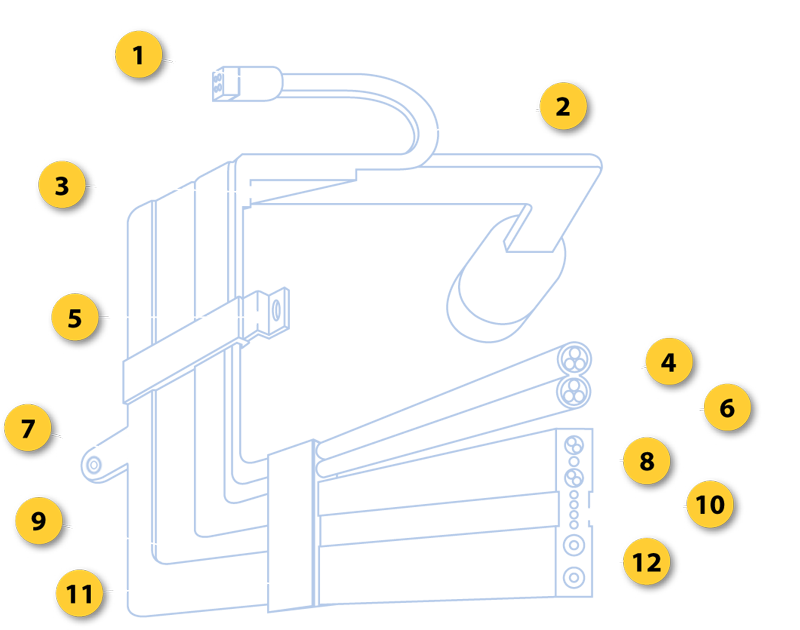

- 1 - Custom Molded Connector Terminations

- 2 - Breakouts

- 3 - Thickened Area for Chafing Protection

- 4 - Contoured

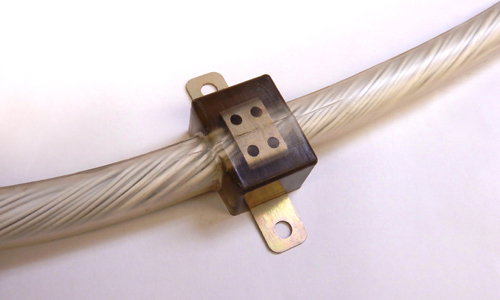

- 5 - Molded-in Cable Clamps

- 6 - Split Sections

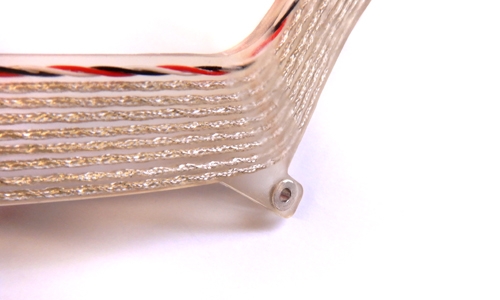

- 7 - Molded-in Eyelets

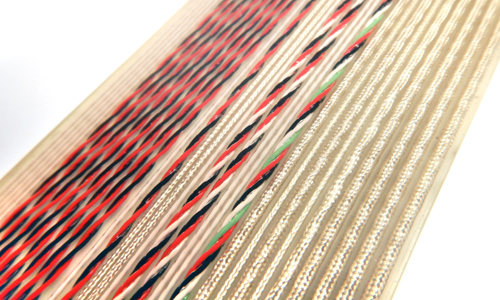

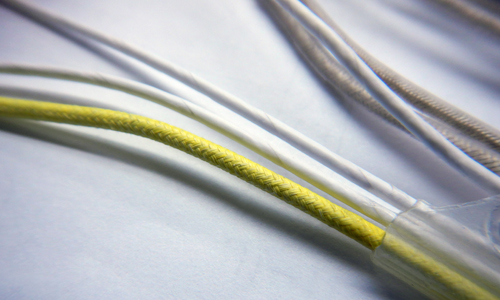

- 8 - Multiple Wire Types and Gauges

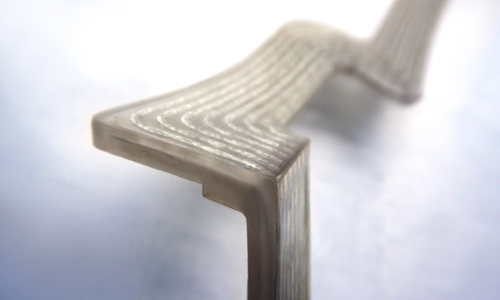

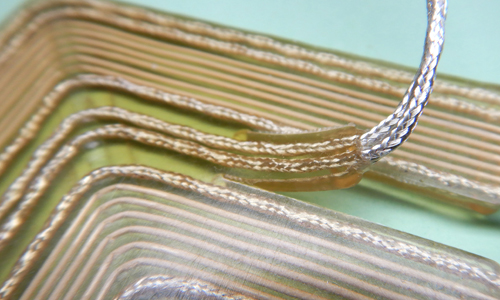

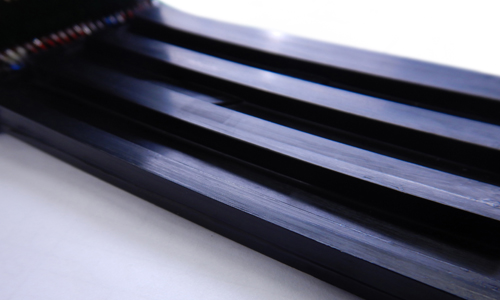

- 9 - Flat Profiled Bends

- 10 - Thick and Thin Areas

- 11 - Reinforced Clamping Area

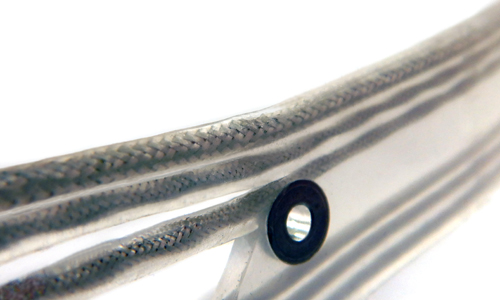

- 12 - Coaxial

Benefits of Molded Flat Ribbon Cable Interconnects

-

Flexibility

Ribbon cables will remain flexible and operational at temperatures as low as negative 100° F and as high as 500° F.

-

Flex Life

Ribbon cables can withstand millions of flexes without electrical or mechanical failures.

-

Repeatability

Since all ribbon cables are mold controlled, there will be no variations in size, shape, and weight.

-

Reliability

The entire assembly is molded from connector to connector making it impervious to moisture, wire breakages, and shorts.

-

Circuit Integrity

Since each wire is always in the same place in the ribbon with respect to all other wires, signal repeatability is constant and crosstalk is eliminated.

-

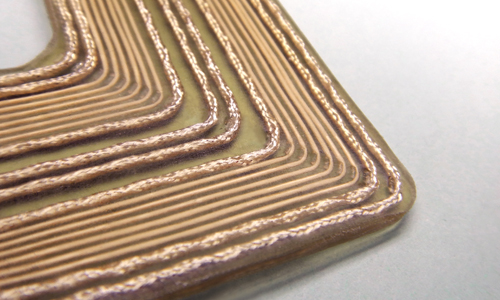

Abrasion Resistance

Polyurethane ribbon cables are resistant to chafing and abrasion resulting from exposure to extreme vibration.

-

Weight Reduction

Since the wires lay parallel to each other and do not touch in the ribbon, it eliminates the need to insulate shielded wires, thereby reducing weight. Bulky metal backshells and strain relief adapters are omitted as a result of molding the ribbons to the connectors.

-

Ease of Installation

Brackets, clamps, eyelets, and clamping areas can be molded into the cable assembly, allowing precise mounting of the cable.

-

Flexible EMI Shielding

Conductive Coatings are applied from connector to connector, i.e., across the encapsulation areas and covering the ribbon. A thin, protective sealant is then applied over the conductive coating. This method of shielding, when compared to the traditional metal over-braid, maintains flexibility, weighs less and reduces the overall volume.